Inverter

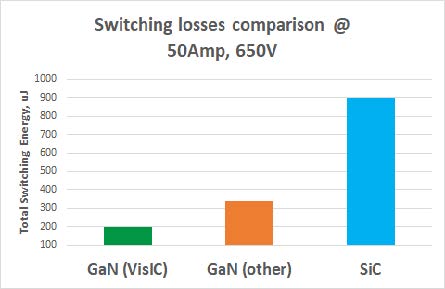

Drive-line system improvement is the key element in the high growth electrical vehicle market. The reduction of drive-line losses combined with lower cost will positively impact the total electric car customer value due to cut back battery size and driving distance extension. VisIC’s D3GaN (Direct Drive Depletion-mode GaN) technology has been proven to reduce the power losses by at least 50% while benefiting from the high-yield, low-cost proprietary design of GaN transistors. VisIC’s packaging technology was developed to ensure high thermal conductivity to best utilize the semiconductor capabilities. This optimization is important for the Inverter design and manufacturing in order to minimize the required paralleling and to optimize the Inverter cost. Using VisIC’s discrete power device enables high design flexibility without sacrificing the thermal benefits of a module.

Deep-dive

The key elements of Electric Vehicles are the electric motors, the battery, and the power electronics that control the driveline capability of the system. Inverter efficiency impacts the longevity of a battery charge, and VisIC Technology’s D3GaN offers superior unmatched performance in this domain. Other factors include the battery technology used, road conditions, and characteristics of the motor.

The inverter is a key part of the drive chain with the function of converting the direct current (DC) power from the main battery into alternative current (AC) power that drives the motor. This conversion comes from a complex sequence of switching events which reconstruct an AC signal from the DC output of the battery. The power losses of the switches, aka power transistors or VisIC D3GaN in our case, have a direct affect on the efficiency of conversion from DC to DC – the lower the switching losses the more efficient is the inverter. VisIC Technologies offers D3GaN (Direct Drive Depletion-mode GaN) products to be used in the creation of efficient inverters either as discrete products or integrated into module packages. In comparative studies, the efficiency of D3GaN in an inverter topology showed that losses of D3GaN were just 15% of those of Si technology and 50% of those of SiC technology giving it a substantial advantage in efficiency. There is an added advantage that D3GaN delivers high power at high frequency resulting in further efficiency increases if paired adequately with the appropriate electric motor. All of these factors mean that use of D3GaN increases the driving range of the xEV and reduces the cost of the electric car.

The inverter is a critical element in the drivetrain and its reliability is of the utmost importance. VisIC technology’s D3GaN is an extremely reliable technology, on a par with incumbent SiC devices and better compared to standard enhancement-mode (E-mode) GaN due to the gate being extremely robust.

In summary for inverter applications, the D3GaN product from VisIC Technologies is an eminently suitable switching element for use in inverter circuits. The superior switching performances and extremely low loss characteristics provide an opportunity for designers to improve overall system performance and ultimately contribute to extending the range of xEVs.