“E-mobility engineering”: The route forward?

“EV users who need to prioritize safety and running costs should look to onboard chargers. Rory Jackson examines the engineering and technology inside them.”

Winter 2020 | E-Mobility Engineering

VisIC Technologies as an expert in On-Board Charger field:

“The viability of electric and plug-in hybrid vehicles depends on how quickly, efficiently and safely their battery packs can be recharged. At the moment, the charging times are as much of a bottleneck on the wider adoption of EVs as their range limits.

By and large, EV charging architectures can be divided into two categories – onboard charging systems, and ‘off-board’ fast DC charging stations.

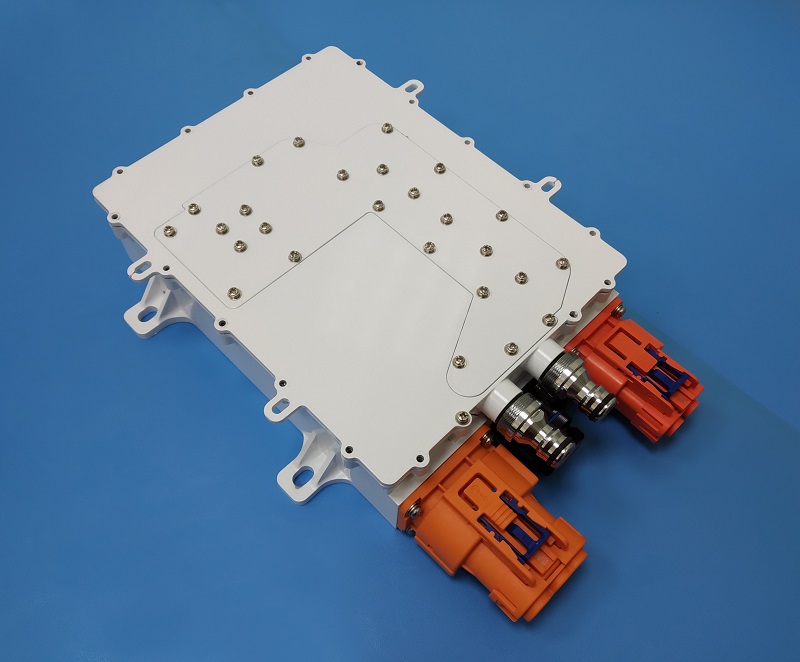

Incorporating onboard chargers are seen by some end-users as a key limiting factor in EV recharge times. The hours taken to charge a battery can be calculated by dividing the energy storage (kWh) by the kilowattage of the charging componentry, and a 6.6 kW onboard charger will only deliver as much power as its rating indicates, even if a 22 kW AC station has been plugged into it.

But while some would, therefore, see fast-charging DC stations and connectors – in which high-power stationary AC-DC inverters are installed on the ground instead of the vehicle – as vital to reducing EV downtimes, the high charging currents associated with this approach inevitably harm the electrode materials of the batteries and shorten their lifespans. That drives up pack replacement rates and thus the costs of owning and operating battery EVs.”